OSCAR

PREDICTIVE CONDITION MONITORING

OVERVIEW

Railway operators are continuously looking for ways to prevent catastrophic incidents such as derailments or collisions. Operators have invested heavily in asset protection devices that help with the early identification or prediction of failures.

OSCAR’s success has resulted in an astonishing array of instruments being fitted to railways around the world anything from a simple brittle bar derailment detector, to highly technical video and laser measurement devices. These calculate anything from heat, wear patterns, angle of attack and much more.

The devices produce a staggering amount of information. With some railways operating hundreds of devices across a huge expanse of territory, the amounts of data produced can be massive. Users must spend extensive time cross-referencing data in spreadsheets and searching for information within various systems. When such volumes of data are available, problems can be missed and errors will indefinitely occur.

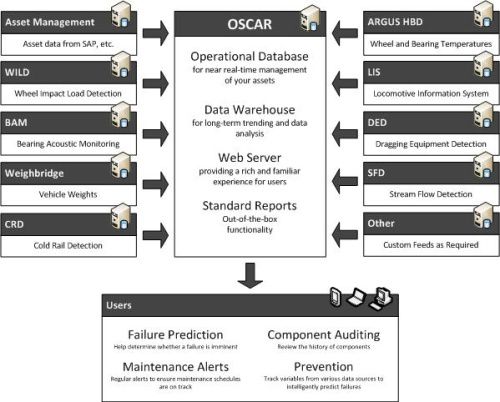

The OSCAR system has been designed to integrate data from all asset protection systems, providing an automated predictive maintenance system, thus drastically reducing human errors.

FEATURES

- Asset Protection data repository system

- Web-based application - accessible anywhere

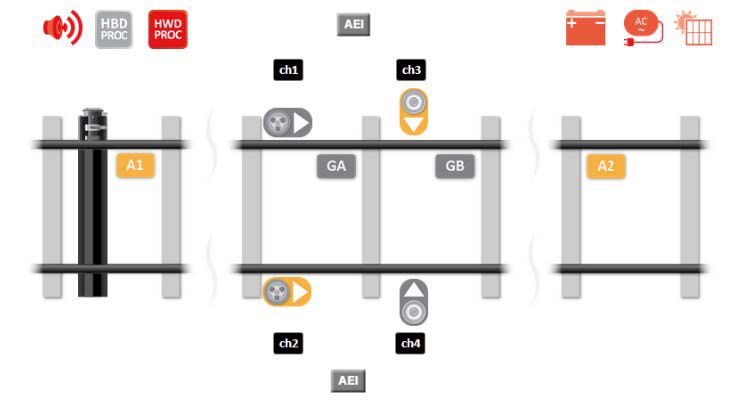

- Collects information from Argus, LIS, WILD, BAM, Weighbridge, DED, SFD and other reporting systems

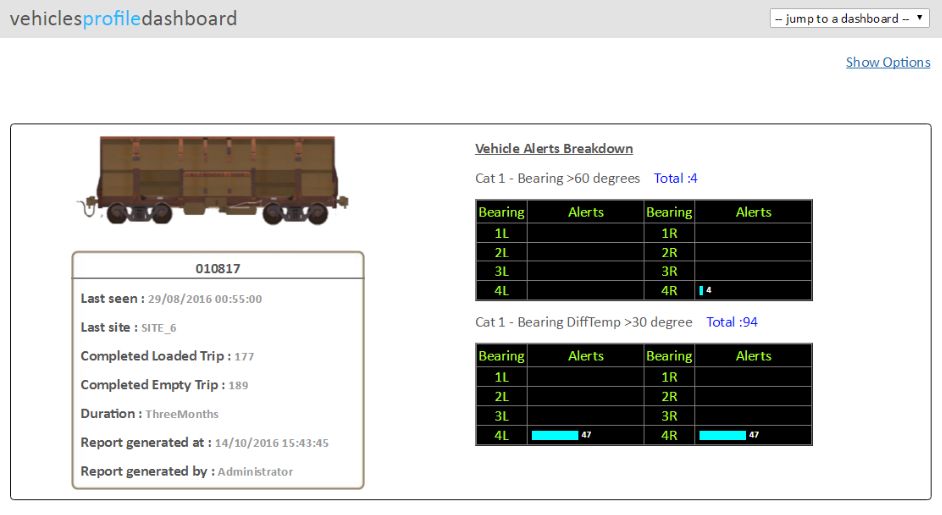

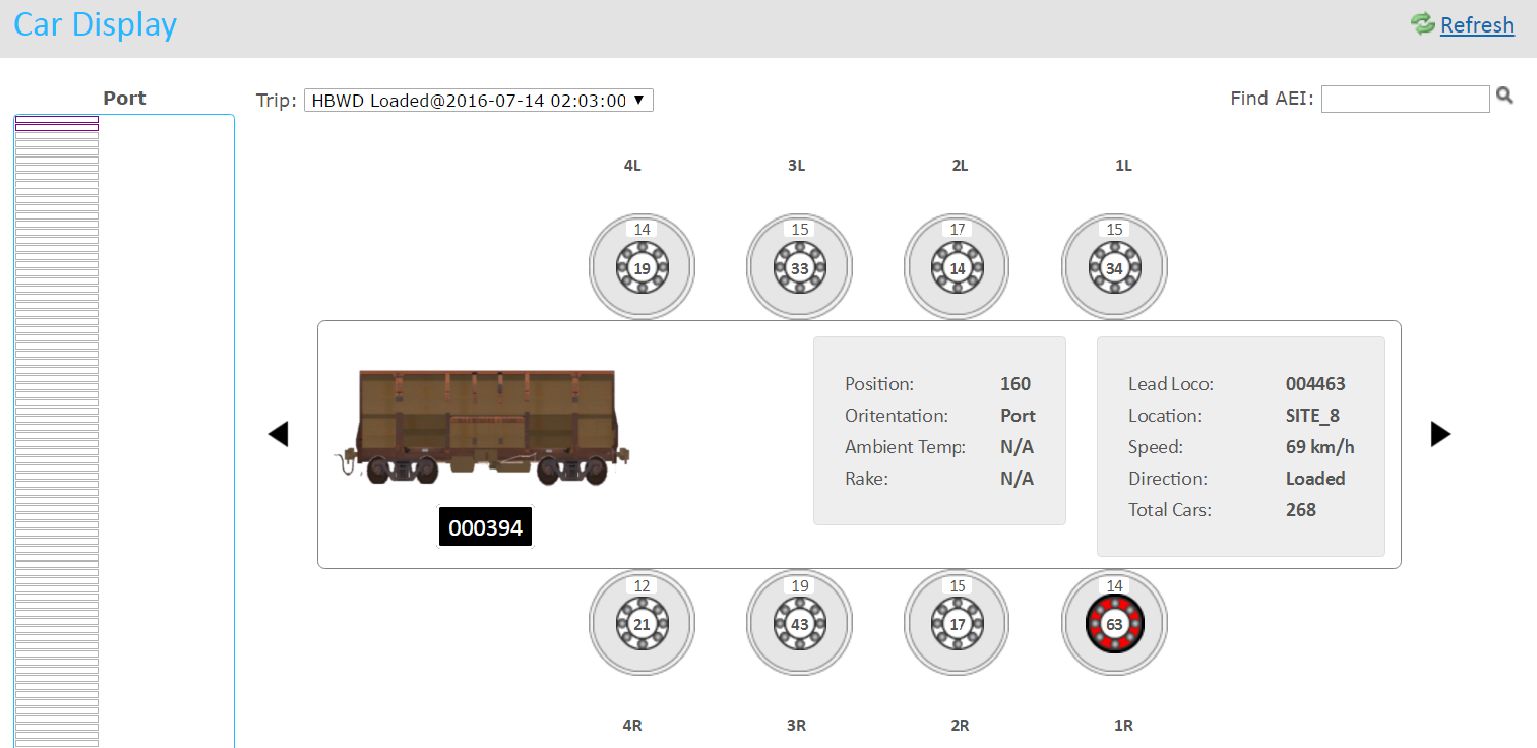

- Provides history for each component of each asset

- Tracks bearings, wheels or other components by serial

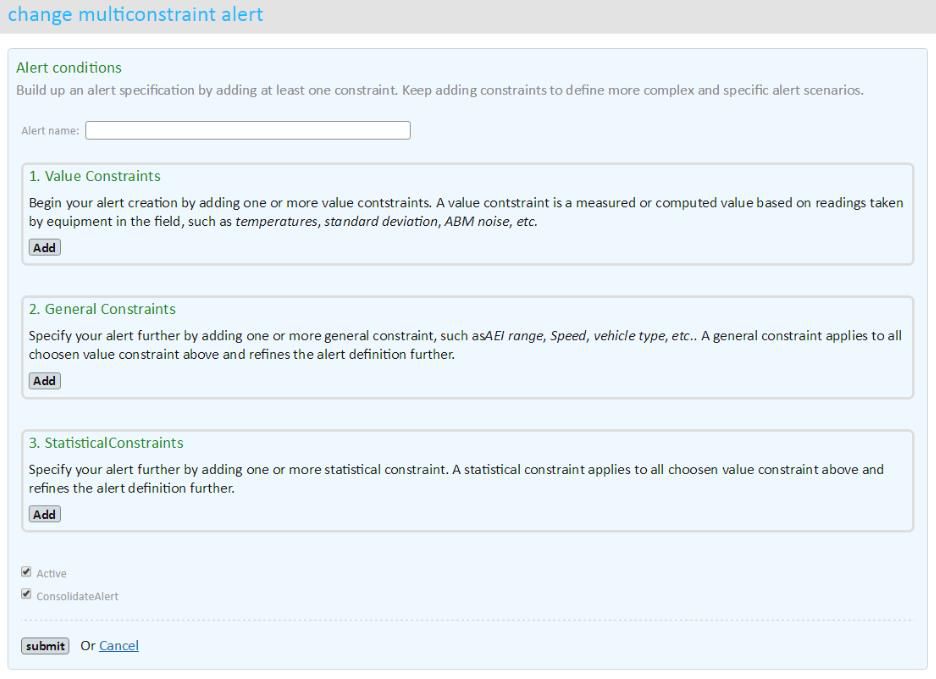

- Automatically calculates maintenance alerts

- Advanced search functions

- Interfaces to the client's maintenance database

BENEFITS

- Combination alerts based on data from multiple device types

- Retention of tribal knowledge

- Reduced training costs through the provision of a single system interface

- Automation of alerts and maintenance orders

- Automated and on-demand reporting system

- Integration with other business systems to allow operational information to be incorporated

- Standards-based reporting, including AAR conventional layouts

- Flexible and easily configured customization to each railway and user’s operation

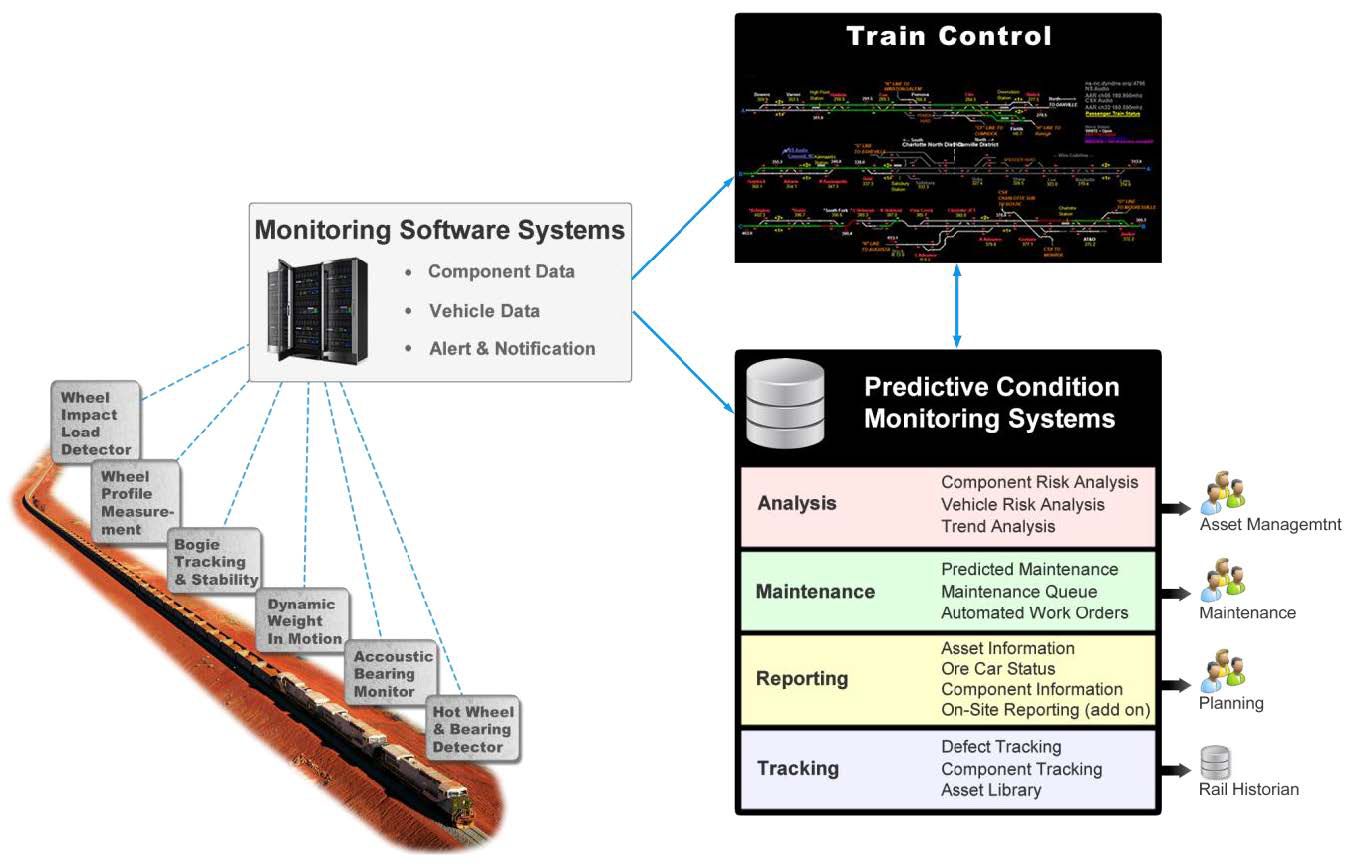

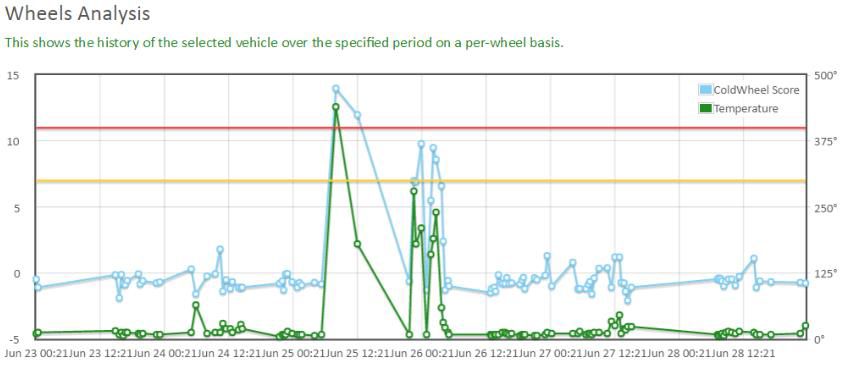

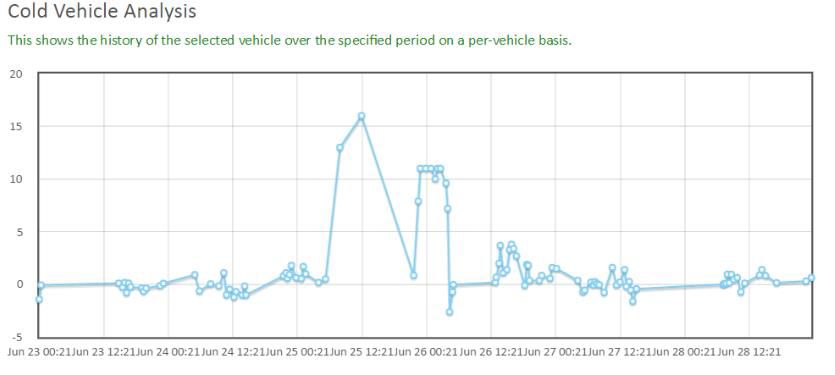

OSCAR collects, compiles and analyses data from various types of asset protection devices (both wayside and on-board) to create a composite view of railway vehicle performance.

OSCAR provides a single interface to obtain all information about the health of the assets being monitoring. This allows users to drill down to existing interfaces from each asset protection system. It is a large warehouse performance data that is surrounded by application layers that allow users full access to said data at the most beneficial level. The database is structured to allow the addition of new monitoring devices or sources of data with ease.

Data has proven valuable in testing through the comparative relationship between differing loads, speeds and braking events prior to arrival and a Hot Bearing and Wheel Detector (HBWD). OSCAR also includes data from the Wheel Impact Load Detector (WILD), Bearing Acoustic Monitor (BAM), Dragging Equipment Detectors, Wheel Profile Measurement Systems (WPMS), Brake Block Monitoring Systems and Stream Flow Detection Systems. These are used to provide further information about the condition of railway vehicles. This information is used to score against readings and generate independent reports based on their alarm thresholds and values.

Benefits are derived through the delivery of the processed information as quickly as possible. Within the limits imposed by available communication systems, OSCAR provides near real-time notifications of important events on monitored vehicles to its users. This is particularly useful for maintenance crews to cull rail vehicles in need of immediate repair.

OSCAR reduces maintenance costs by lowering the incidence of unnecessary maintenance or service on vehicles. It also enables higher utilization and lower costs through scheduled maintenance at facilities when railcars are empty. In addition, OSCAR can monitor post maintenance performance to provide a quality control check on the maintenance performed.

When used in conjunction with software such as Progress Rail’s Locomotive Information System (LIS), OSCAR can also provide valuable information on locomotive and driver performance.

APPLICATIONS FOR OSCAR

Management

- Fleet utilization

- Maintenance planning

- Improve maintenance regimes and training

- Targeted training for personnel and divisions

- Evaluate different suppliers and models

- Customize automatic alerts for maintenance personnel

Analytical Personnel

- Search/export component history

Maintenance Personnel

- Analyze automated alerts

- Search vehicle/component history

- Compare data across multiple locations and data sources

DASHBOARDS

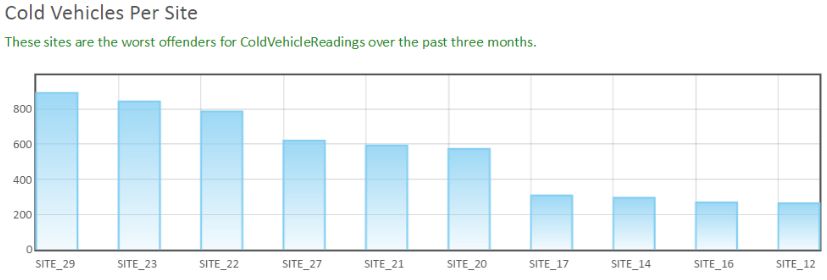

Dashboards can also be created to identify trends, provide hit lists (i.e. Top 10 Alerts) or analyze bearing and wheel group performance. OSCAR provides a simple to use dashboard system that allows users to generate graphical reports including:

Dashboards can also be created to identify trends, provide hit lists (i.e. Top 10 Alerts) or analyze bearing and wheel group performance. OSCAR provides a simple to use dashboard system that allows users to generate graphical reports including:

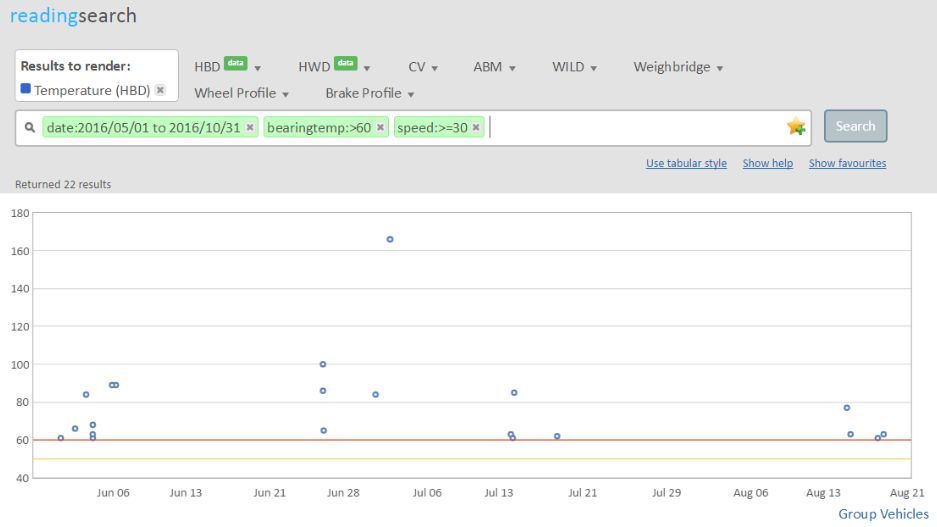

PLAIN LANGUAGE SEARCH FACILITY

OSCAR utilizes a simple to use search facility. Plain language text and simple to use point-and-click help systems allows users to form complicated queries in seconds. The same search parameters are used when building a dashboard as searching data – simplifying the promotion of users to manage, quickly, and with no additional training.

WEB-BASED USER INTERFACE

By using industry-standard web-based user interface technology, OSCAR has been developed to minimize the effort to access the system. Benefits to this include:

- Function through firewalls: as web-based technology is rarely blocked, access from clients is normally allowed by IT administrators without further changes to firewalls, ports or application verifications

- Function on most devices: the basic technology used by OSCAR means that a client can access it from almost any device, including smartphones, tablets and PCs

- OSCAR has also been programmed to minimise the number and types of plugins that are used. This means that IT departments don’t need to install additional software for users to be able to unlock the benefits of the software

- Remote maintenance can be performed through web ports, by either Progress Rail staff or local administrators

- Remote deployment: data can be hosted almost anywhere, including on Progress Rail’s own cloud servers (subject to device data availability)

BUSINESS SYSTEM INTEGRATION

OSCAR has been designed to integrate into other business systems, including:

Rail Historians

- Access train name information

- Raise alert notifications

Maximo

- Retrieve serial numbers, vehicle configuration

- Generate work orders

SAP

- Access train name information

- Raise alert notifications

- Retrieve serial number vehicle configuration

Web Services

- Retrieve serial number vehicle configuration

- Access train name information

- Raise alert notifications

- Retrieve serial number and vehicle configuration

- Retrieve current location (track and node) information

OEM sockets

Access train name information

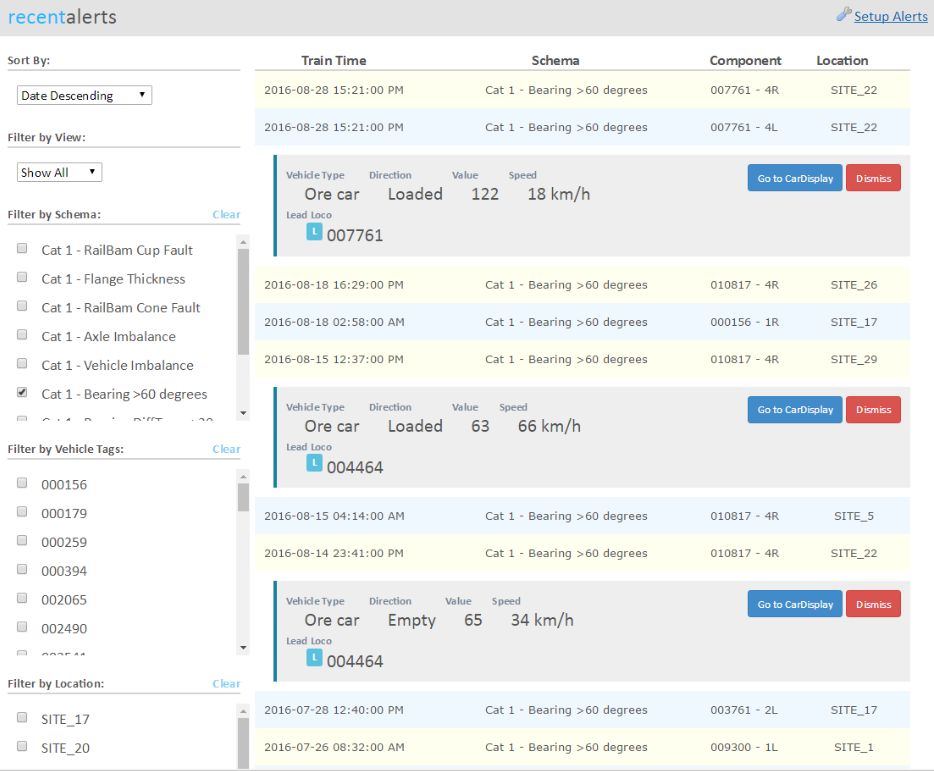

AUTOMATED ALERTS

OSCAR is designed around the principle of augmenting the human factor when analyzing asset protection data. As such, it is necessary for interfaces to be utilized to pass the results of this analysis to down-stream systems. The alerts are capable of being sent to multiple systems and currently include:

- Email to users and/or maintainers, with hyperlinks to OSCAR with the data causing the alert

- SMS to out-of-office personnel

- SAP integration to raise notifications and work orders

- Maximo integration to raise notifications and work orders

- Generic ODBC to raise notifications and work orders

Additional interfaces are readily defined and implemented within the OSCAR architecture, allowing alerts to be passed via different mechanisms to other systems.

HISTORIC RECORDS

- Vehicle History

Select readings for a vehicle by specifying the date range and AEI number

AUTHENTICATION

User Authentication levels allow individual users or groups of users to receive alerts, notifications and administrative privileges. This allows Condition Monitoring teams to work on identifying trends and potential performance issues, without affecting on-going operations and alerts. Users can be segmented into those who are allowed to create and modify alert criteria, and those who can view and action the alerts created. Finally, all activities each user performs that affect the database are logged for later auditing, should it be required.

INDUSTRY STANDARD TECHNOLOGY & PLATFORM

As OSCAR operates on standard Microsoft Server platforms, it is Virtual Machine ready and easy to deploy. This minimizes deployment costs through the use of client-supplied virtualization. Alternatively, Progress Rail can provide a high-availability deployment platform to host the operation.

The benefits of this system extend far beyond their cost. This includes:

- Remote deployment: can be hosted almost anywhere, including virtual environments

- Updates and maintenance are provided for third-party applications, servicing the wider community

- Long-term development and support by Progress Rail staff

- Readily available replacement staff from the wider development community