TRACKWORK

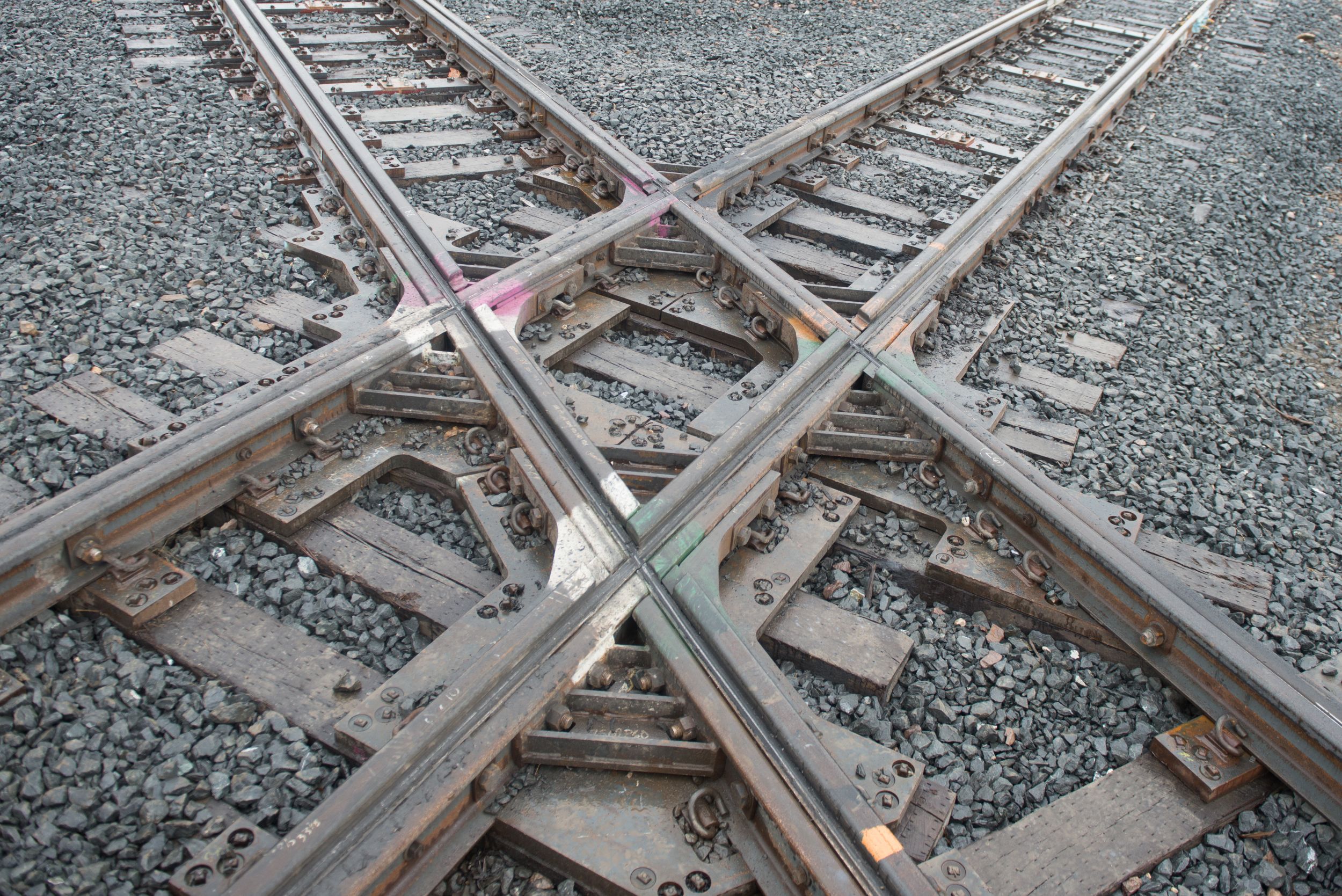

With state-of-the-art manufacturing facilities located strategically around the globe, we produce the highest quality trackwork and fasteners, with 100-plus years of experience in the design and manufacture of cast manganese crossings.

Our products range from complete turnout panels to replacement parts, flash butt welded frogs, lift frogs, taper heel frogs, partial flange bearing frogs, moveable point frogs, OWLS crossings and clamptite adjustable braces. Our specialty products include fixed and sliding buffer stops, overhead line structures, stretcher bars and hollow steel sleepers. Additionally, we have a variety of rail, guard rails, asymmetric switch points and solid monoblock, tri-metallic welded rail leg crossings available to satisfy all requirements.

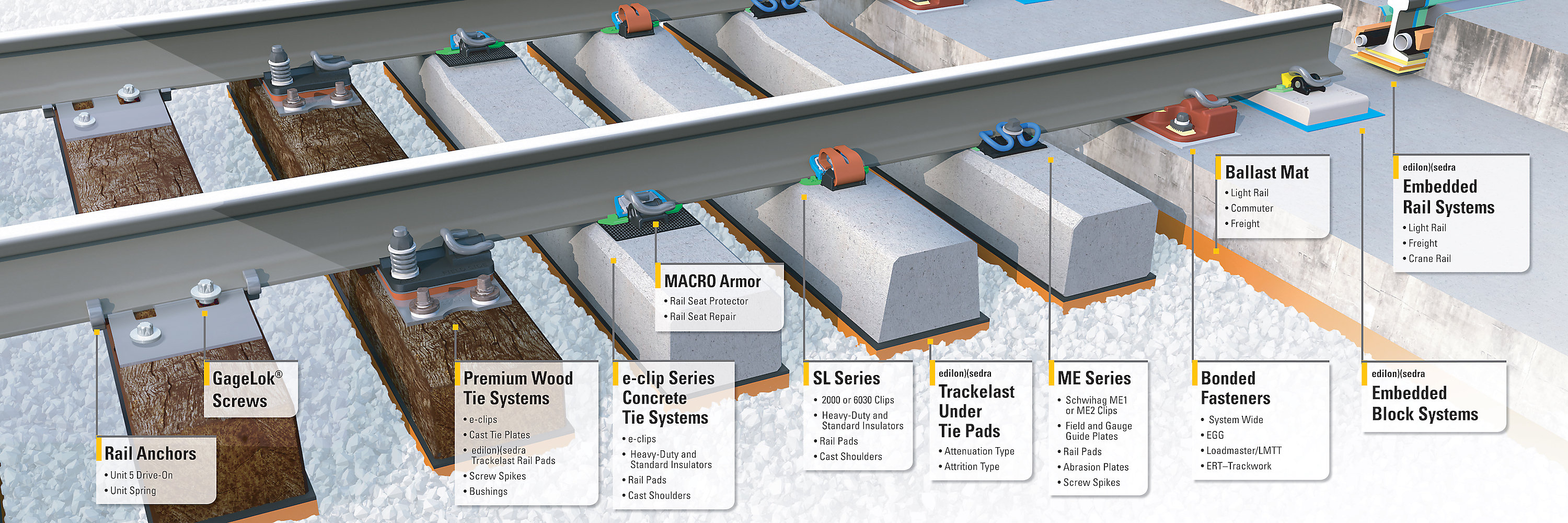

Progress Rail acquired Rail Product Solutions, formerly part of Amsted Rail, in 2016 to capture best-in-class, high-performance fasteners for freight and transit rail customers. Our fastening solutions serve as fundamental components for rail infrastructure, playing a crucial role in enhancing reliability and minimizing track downtime. We support our customers by delivering innovative options, such as the ME Series or MACRO Armor for concrete ties. At the same time, we offer a broad range of traditional products, such as rail anchors, bonded direct fixation fasteners and e-clips.

TRACKWORK

Available Components include, but are not limited to the following:

INFRASTRUCTURE CONTACTS

TRANSIT, SHORT LINE, CONTRACTORS & INDUSTRIAL

West Director - Sales

Libertyville, IL

Phone: 224-545-0524

INTERNATIONAL SALES

International Sales Director

Phone: +1-469-934-8284

Director, International Business Development

Phone: +44 (0) 7966 337924

Business Development Director, LATAM

Phone: +55 (31) 3779-6729

Cell: +55 11 96551-6068

PRS UK Sales Director

Phone: +44 (0) 114 2841 634

Mobile: +44 (0) 7808 897092

Infrastructure - Business Development Manager, Australia

Phone: +61 (0) 408 010 983

SENIOR VICE PRESIDENT - TRACK INFRASTRUCTURE

Office Phone: 256-505-6588

Cell Phone: 256-520-6249

VICE PRESIDENT SALES - NORTH AMERICAN TRACK

Phone: 205-901-9931

-

Fasteners

Progress Rail offers a full line of trackwork, components and fasteners for heavy haul and transit railways, and is a leading manufacturer of specialty trackwork in North America, the United Kingdom and Australia. With state-of-the-art manufacturing facilities located strategically around the globe, we produce the highest quality trackwork and fasteners, with 100-plus years of experience in the design and manufacture of cast manganese crossings.

Learn More -

Rail Services

Progress Rail’s trackwork experience and remanufacturing capabilities enable us to provide quality trackwork to your specifications. Whether you need new rail, recycled rail, Other Track Material (OTM), complete turnout packages or a single trackwork component, our facilities can fulfill your requirements.

Learn More -

Signaling

Progress Rail has long been a signaling provider, designing wayside and highway crossing systems for railroads since 1992. Our signal engineering and asset protection are just some of the many ways we can help your business.

Learn More