Uptime Cloud aggregates big data, storing it safely in a secure environment, ready for analysis. Uptime Connect and Uptime Analytics can access and crunch immense amounts of data quickly through the Cloud’s multiple, scalable entry points.

Uptime Cloud pulls concentrated data and consolidates it into categories, such as asset vitals, model and type, individual and fleet history, weather and geography, priming data for the Uptime Analytics platform.

Uptime Cloud goes beyond data concentration and context by transforming data into actionable insights. The easier customers can scale and determine their data’s worth, the better – working faster and harder with fleets, growing operations in a more profitable manner.

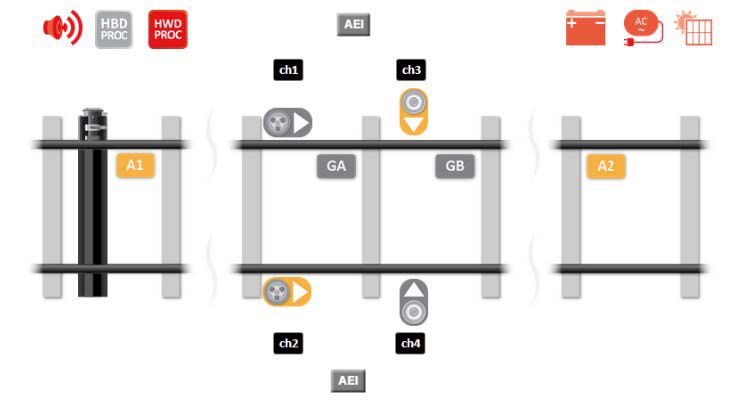

Maintain data security the ACC 4 Slot while efficiently and effectively managing operations. Connect protects rolling data centers and on-board computers by safeguarding against potential unknowns, such as malicious hardware installation. Connect ensures the highest level of security for on-board and off-board networks.

Data accessibility and reliable communications are critical to capturing valuable insights. The ACC 4 Slot uses multiple modems to constantly confer with Uptime Cloud and the railroad’s back-office communications.

Not only does the ACC 4 Slot ensure clear communications for the PR Uptime™ Suite, it also delivers transformative features for Uptime Analytics. Power Doctors can stream live data from assets for situational awareness, providing powerful prognostics. Video feeds, remote fault handling and other features help customers better maintain fleets. At current data levels, connected analytics equate to potential savings of roughly $150K per locomotive, with advanced analytics proving even more valuable.

PR Uptime™ allows railroads to make proactive mission decisions based off predictive alerts and to reduce service delays caused by mission failure. By enabling planned maintenance to replace unscheduled repairs, locomotives can generate more revenue at lower cost.

Uptime Analytics help shops fix locomotives the first time they enter, leading to fewer repeat shoppings and fewer unnecessary shoppings. The target repair and troubleshooting guides from Uptime Analytics focus the repair work to the source of the problem, decreasing shop cycle times. User feedback and repair closeouts facilitate machine learning allowing Uptime Analytics to continuously improve. All of this leads to improved availability of locomotives.

PR Uptime™ predictive analytics provides a reliability index (health score) for locomotives and fleets to help railroads build better trains in less time and with less effort. Additionally, the platform helps users track their locomotives in the yard and creates better situational awareness across the organization using things like geofencing alerts.

Leverage operational data to reinvent how your railroad runs. Move from time- to condition-based maintenance, reduce costs and increase productivity with PR Uptime™ Suite to effectively manage operations.

Our Nitro Decision Support System augments the capacity of humans to objectively find the best course of action.

Learn MoreOur PowerView™ suite of products helps protect your people and assets, and save valuable time and money. From our locomotive event recorder, to fuel monitoring, to our PowerView Connect remote monitoring, we have what you need to keep your railroads rolling.

Learn MoreWhen it comes to predictive condition monitoring systems look no further than Progress Rail. We deliver the most comprehensive predictive condition monitoring systems available on the market today.

Learn MoreTalos™ Train Automation leverages machine learning and artificial intelligence to encode locomotive engineer behavior, analyze train runs, and optimize train operation. Let us know how Progress Rail can help you automate your trains today.

Learn More