KERSHAW® SKYTRIM 75 G3

Progress Rail serves the vegetation management industry with reliable Kershaw® equipment to tackle tough maintenance jobs, accessing sites quickly and easily. Suitable for a variety of applications, our machines can perform tree and brush clearing for utilities, landscaping contractors, golf courses and residential usage, right-of-way clearing and more.

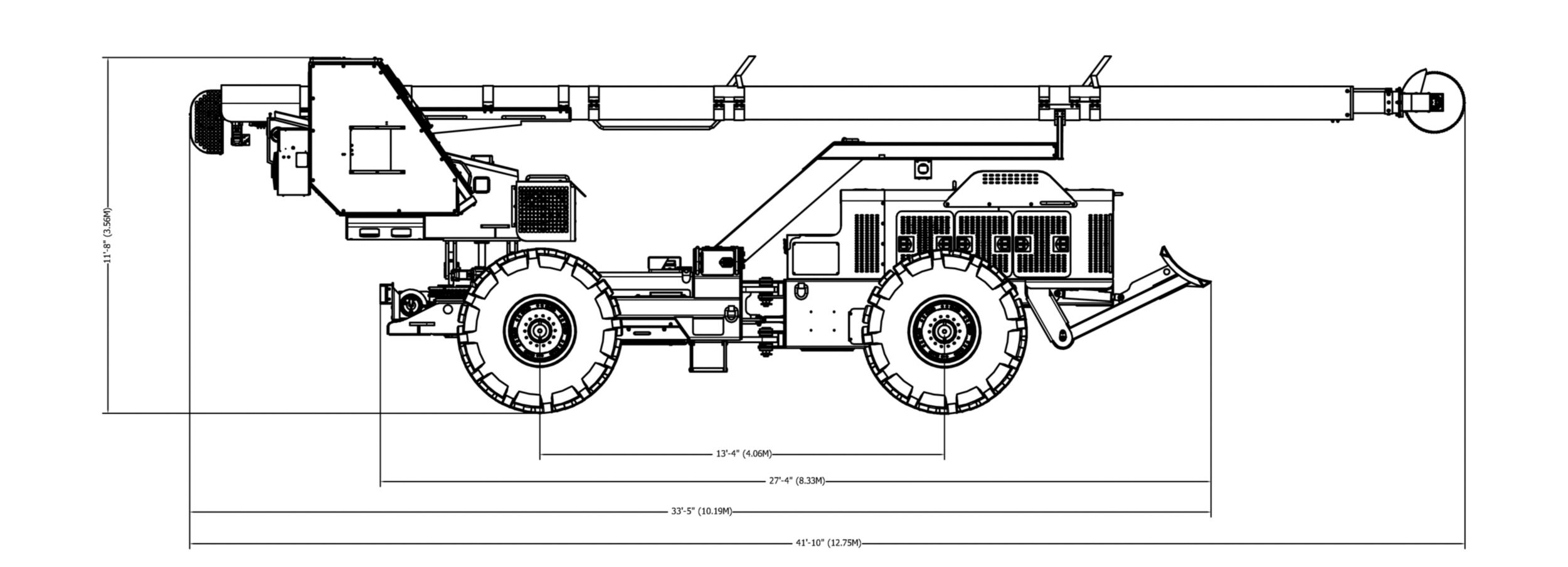

The Model 75 SkyTrim Tree Trimmer is a rubber-tired, telescoping tree trimmer designed for trimming tree limbs and vegetation from utility right-of-ways, construction sights, roadways, etc. in rough terrain. The SkyTrim is equipped with a fiberglass telescoping boom with a saw cutterhead capable of extending to a maximum height of approximately 75 feet (22.86 meters) from the ground.

The SkyTrim 75G3 is now available built to CE/EU specifications with Stage V engine, to be certified in-country. See technical details below.

TECHNICAL DETAILS

SKYTRIM 75G3

CE/EU STAGE V ENGINE

Dimensions: Length = 42'3" Width 10' Height = 11'6"

Weight: Approximately 28,400 lbs (12882 kg) with standard 28L- 26 tires.

Engine: Equipped with liquid-cooled 4.4 liter Caterpillar® diesel engine rated for 131 hp (97.9 kw) @ 2200 rpm and compliant with European Union Stage IV and EPA Tier 4 Final regulations. Open engine compartment for maximum accessibility.

Propel System: Hydrostatic propel motor driving through a heavy duty 2-speed power shift transmission, with a foot switch to activate the differential lock.

Transmission and Axles: 2-speed shift-on-the-go transmission connected by heavy-duty drive shafts to both axles. Heavy-duty Caterpillar® axles with inboard wet disc service brakes. Rear axle is rigid mounted, front axle designed to oscillate. Equipped with a foot switch to activate differential lock.

Wheels, Tires and Brakes: Tires: 28L-26 logger type tire standard. Service brakes are wet disc inboard hydraulically applied and “built-in” the axles. Parking brakes are fail-safe spring applied/hydraulic-released wet disc driveline mounted. Parking brakes will automatically apply if engine stops or hydraulic system pump fails.

Hydraulic System: Engine driven pump drive. Hydrostatic propel system consists of closed loop pump driving a hydraulic propel motor mounted on transmission Charge loop filtration. Hydraulic reservoir mounted at the rear of engine compartment with cleanout port and shutoff valve. Equipped with electric emergency pump. Upper structure tilt system, rotate system, and boom up/down system equipped with lock valves.

Electrical System: 24 volt dc negative ground with engine driven alternator and two 12-volt batteries w/1000 cold cranking amps each. Equipped with safety electric strobe light and backup alarm.

Capacities: Fuel: 90 gal (340.7 liters), Hydraulic: 13 gal (49.21 liters)

Cab: Equipped with 1 1/4” tinted Lexgard® top, engine instruments, and ergonomic seat. Equipped with light touch hydraulic pilot pressure joystick for extend-lift-swing-tilt boom controls, convex mirror, secondary exit, standard wiper and A/C & Heating console. Heavy duty swing bearing with worm gear drive for maximum tooth engagement. Floor is fully enclosed. Access door is full length tinted Lexgard® with positive latch.

Boom: Telescoping composite construction with 75 ft. (22.86m) reach from ground. Telescoping boom driven with #50 chain. Each unit is electrically insulated and tested to ANSI A92.2-2001 Category C standards to 100 kv for maximum operator safety. Equipped with single 24 inch (609.6mm) diameter carbide-tipped saw turning @ 2800 rpm.

Optional Equipment: Front mounted winch, tire sizes, fire extinguishers, rear view camera, and CE lighting package. Other options available upon request.

QUICK START GUIDE

PARTS HOTLINE: 1-888-660-5252

SERVICE HOTLINE: 1-833-537-7782

SALES CONTACTS

VEGETATION EQUIPMENT SALES

RAIL EQUIPMENT SALES

OEM PARTS, SERVICE & WARRANTY

INTERNATIONAL SALES

KERSHAW DIRECTOR

Hal Acree

National Sales Manager - Vegetation/Utility

Lafayette, IN

765-404-2550

Mark Book

Account Executive - Vegetation/Utility

Montgomery, AL

502-432-9302

Carlton Hardman

Account Executive

Montgomery, AL

251-583-3704