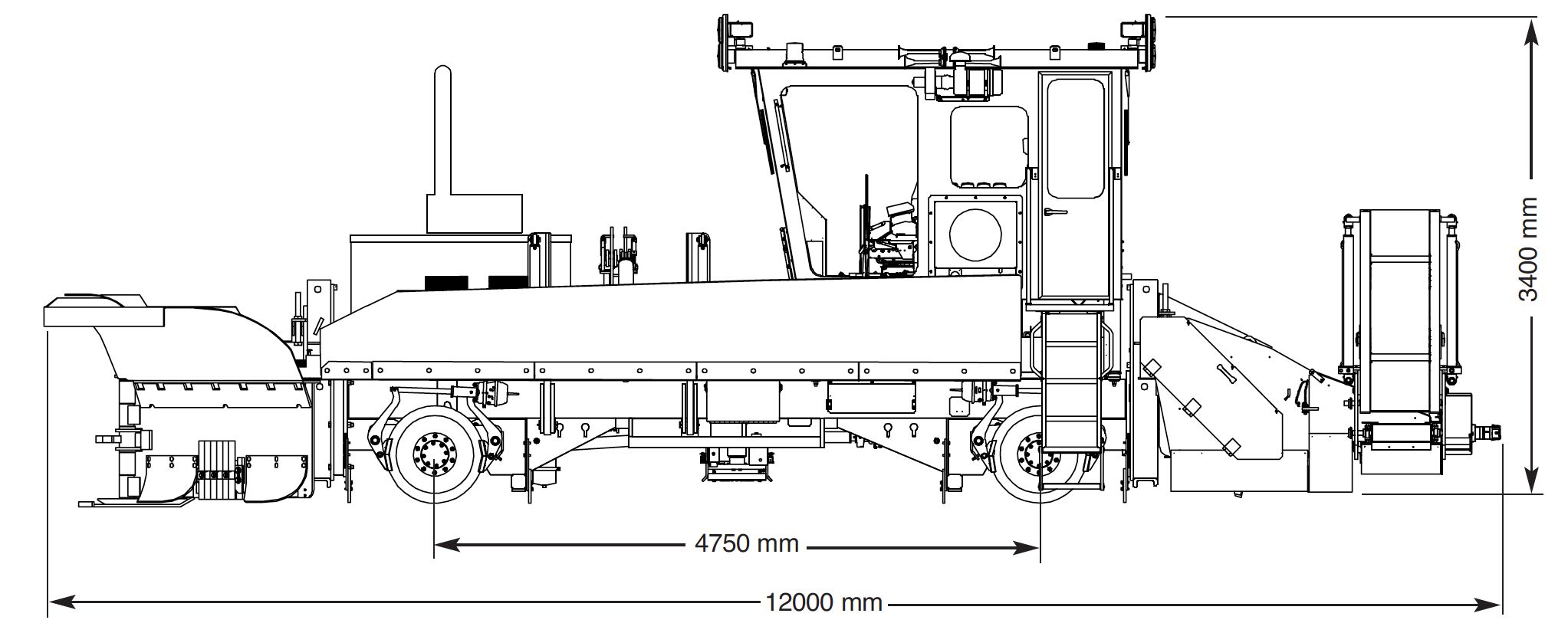

KERSHAW® MODEL 60 SAND REMOVER

Progress Rail’s Maintenance-of-Way (MOW) division was born out of the movement toward mechanization in the railroad industry and introduced the first Kershaw® Ballast Regulator in 1945. Today, Progress Rail supplies Kershaw® MOW equipment, providing machines to all Class I railroads, transit and short lines and contractors around the world.

The Kershaw® Model 60 Sand Remover is equipped with a sand transfer plow, benching-type sand wings and a broom/conveyor attachment for sand removal from the track area. The sand transfer plow removes sand up to 6 meters either side of track centerline. Sand wings remove sand up to four meters either side of track centerline. Conveyor attachment discharges sand from broom at six meters from track centerline. Multi-stage conveyor allows width to be minimized to less than three meters from the track centerline to clear obstructions.

TECHNICAL DETAILS

Frame: Welded construction using 4 (101.6 mm) x 12 (304.8 mm) solid steel side members and structural steel cross members.

Weight: 50,020 lbs. (22689 kg)

Engine: Caterpillar® C9.3B, 335 hp @ 2200 rpm.

Propel System: Hydrostatic drive, variable displacement piston pump, variable displacement piston propel motor. Travel speed: 50 mph (80 km/hr); Work speed: 12.4 mph (20 km/hr).

Transmission and Axles: Hydraulic propel motor powers a 4-speed “shift on the go” transmission. Dual propeller shafts, two (2) spring-mounted 30,000 lb. (13608 kg) industrial type axles equipped with no spin differential. Equipped with 9 leaf spring suspension. A single control handle controls speed and direction in each range.

Wheels and Brakes: 28" (711 mm) cast steel wheels bolt-ed to each axle, external clasp brakes (two shoes per wheel). Service brakes; air applied/spring released. Parking brakes; spring-applied/air released.

Electrical System: 24-volt dc negative ground, 150 amp alternator, two 205 amp/hour batteries, color-coded and numbered wiring.

Air System: Air compressor, engine oil lubricated, camshaft driven, water-cooled, 13 ft 3 (.37 m3/min) free air volume @ 1250 rpm. System pressure is 100-120 psi (758-927 kPa), 613 in. 3 (10 liter) air tank. Service brakes are controlled by a pressure reducing valve and the parking brakes by a manually-operated dump valve. System is also equipped with a dual-tone air horn, safety relief valve.

Hydraulic System: Engine-powered pump drive with clutch drives hydrostatic propel pump and pumps for controls and broom. Control circuit includes two pilot-pressure joysticks with electronic keypads, electrically actuated control valves and remote-mounted oil cooler. 100 mesh (145 micron) suction screens and 10-micron return filters. Electric emergency pump to operate selected circuits.

Cab: Extremely roomy cab. Fully enclosed and insulated with safety glass, dome light, dual front windshield wipers, and ergonomic seats. Cab access from either side of the machine. Equipped with self-contained vertical mount sidewall heater/air conditioner. The cab is 75 inches wide (1905 mm) and 88 inches high (2235 mm).

Capacities: Fuel: 122.5 gal (464 liters), hydraulic: 98 gal (371 liters).

Options: V-Type Sand Plow

KERSHAW® MOW OVERVIEW

PARTS HOTLINE: 1-888-660-5252

SERVICE HOTLINE: 1-833-537-7782

SALES CONTACTS

RAIL EQUIPMENT SALES

VEGETATION EQUIPMENT SALES

INTERNATIONAL SALES

OEM PARTS, SERVICE & WARRANTY

KERSHAW DIRECTOR

Randy Chubaty

National Sales Manager - Rail

Fairmont, MN

507-384-2577

Jennifer Kincaid

Sales Executive - Rail

Bradenton, FL

414-369-9290