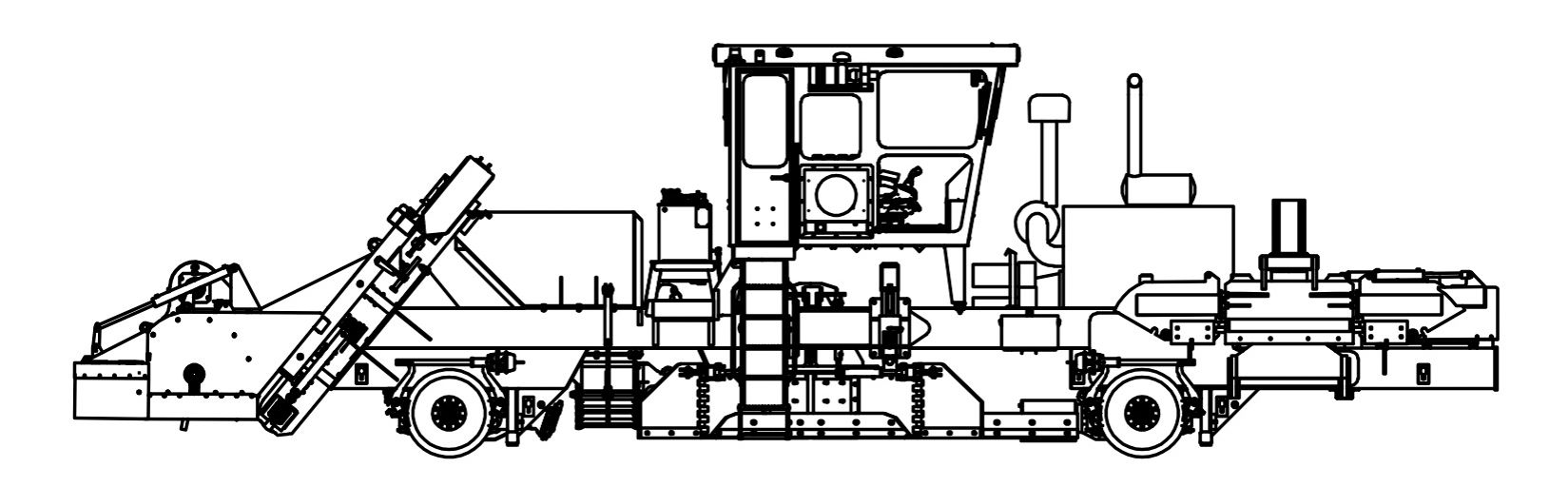

KERSHAW® BALLAST REGULATOR MODEL 66

Progress Rail’s Maintenance-of-Way (MOW) division was born out of the movement toward mechanization in the railroad industry and introduced the first Kershaw® Ballast Regulator in 1945. Today, Progress Rail supplies Kershaw® MOW equipment, providing machines to all Class I railroads, transit and short lines and contractors around the world.

The Kershaw® Model 66 Ballast Regulator features a center-mounted plow, reversible wings, and a broom with conveyor and hopper assembly making it a powerful machine for ballast shaping, shoulder profiling, and a variety of other track maintenance operations.

TECHNICAL DETAILS

Frame: All welded construction using tubular sections with formed and structural cross members.

Cab: Two-man, fully enclosed, and insulated with safety glass, dome light, front windshield wipers, and sliding side windows. Cab is climate controlled.

Engine: Caterpillar C9.3, 350 hp @ 2200 rpm. Liquid-Cooled Diesel.

Propel System: Hydrostatic variable volume pumps and motors. A single lever controls both speed and direction in each transmission range.

Travel Speed: 50 mph

Transmission and Axles: Two-speed transmission at each axle is hydraulically driven. The axle is attached to the main frame by means of a coil spring suspension at each end and supported by AP bearings.

Wheels and Brakes: 33" (838 mm) diameter cast steel wheels are pressed onto the solid axles. Brakes on each wheel are clasp-type applying external cast iron brake shoes to the wheel tread. Service brakes are air applied/spring released. Emergency/parking brakes are spring-applied/air released. A separate train line brake system is provided.

Air System: Air compressor is engine oil lubricated, water-cooled 16.8 CFM volume at 1250 rpm. System pressure is 110 psi. Service brakes are controlled by a pressure reducing valve and the parking brakes by a manually operated dump valve. A train line brake system is provided for the unit.

Hydraulic System: Pump drive powers hydrostatic propel pump as well as pumps which power broom, conveyors, wing and plow operation. Equipped with 100 mesh suction screens and 10 micron return line filters.

Hydraulic Pressures:

Propelling Pressure control: 5,500 psi (37,9211 kPa)

Cab Front Console Valve Banks: 2,500 psi (17,237 kPa)

Broom Motor: 1,850 psi (12,755 kPa)

Electrical System:

24 volt DC negative ground, 95 amp alternator, two heavy duty batteries with color coded and numbered wiring.

Capacities:

Engine Lube System: 8.5 gal (32 liters)

Fuel Tank: 140 gal (530 liters)

Hydraulic Tank: 110 gal (416 liters)

Pump Drive: 4 1/2 quart (4.2 liters)

Transmission: 39 quart (36.9 liters)

Physical Data

Length: 43ft (13106.4 mm)

Width: 9ft 10in (3000 mm)

Height: 12ft (3657.6 mm)

Wheelbase: 22ft 6in (6858 mm)

Weight: 68,000 pounds (30853 kg)

Special Features:

Conveyor and 5 m3 Hopper Assembly.

KERSHAW® MOW OVERVIEW

PARTS HOTLINE: 1-888-660-5252

SERVICE HOTLINE: 1-833-537-7782

SALES CONTACTS

RAIL EQUIPMENT SALES

VEGETATION EQUIPMENT SALES

INTERNATIONAL SALES

OEM PARTS, SERVICE & WARRANTY

KERSHAW DIRECTOR

Randy Chubaty

National Sales Manager - Rail

Fairmont, MN

507-384-2577

Jennifer Kincaid

Sales Executive - Rail

Bradenton, FL

414-369-9290