KERSHAW® 38-7 KRIBBER ADZER

Progress Rail’s Maintenance-of-Way (MOW) division was born out of the movement toward mechanization in the railroad industry and introduced the first Kershaw® Ballast Regulator in 1945. Today, Progress Rail supplies Kershaw® MOW equipment, providing machines to all Class I railroads, transit and short lines and contractors around the world.

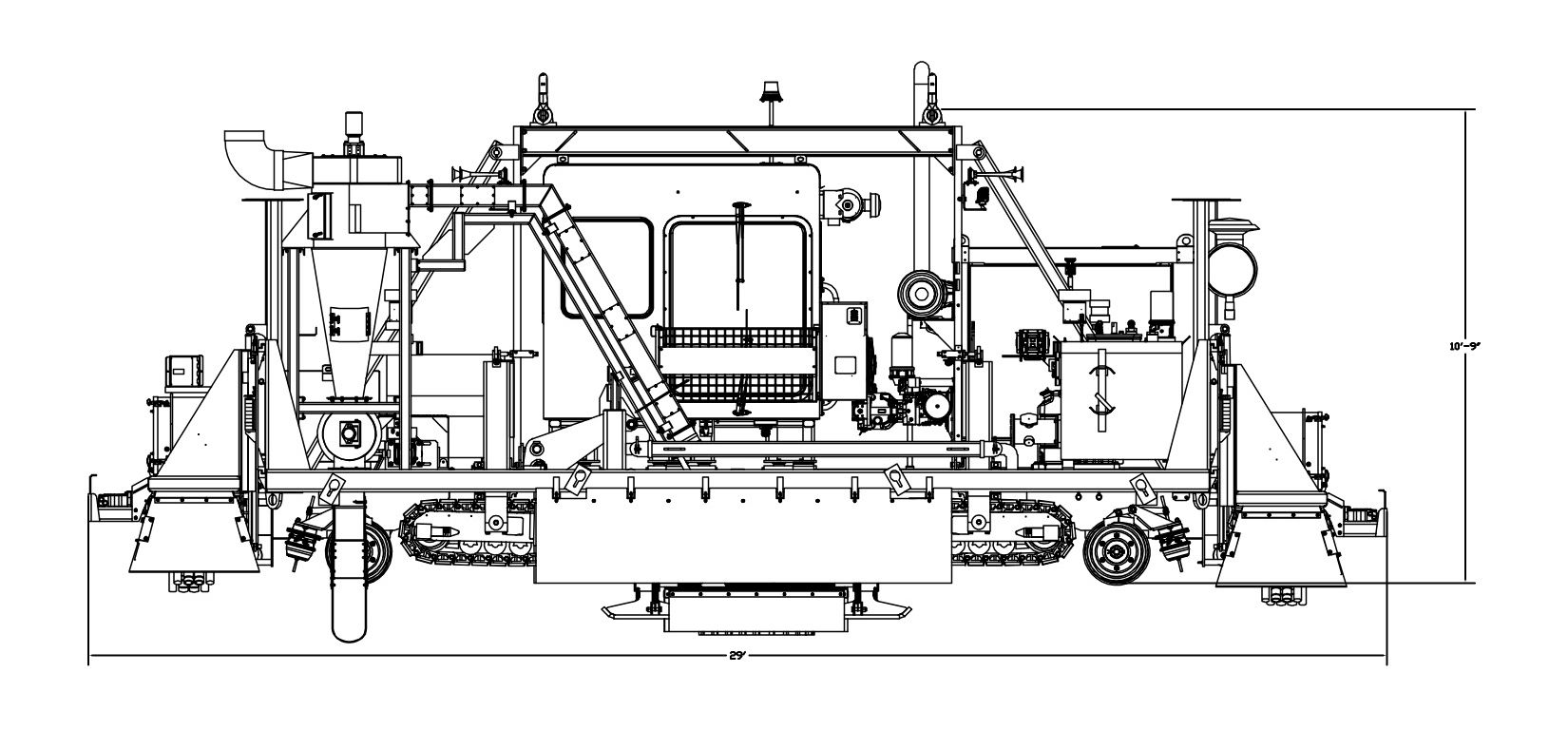

The Kershaw® 38-7 Kribber Adzer performs the task of ballast removal from between ties at the tie plate area, then adzes the cross ties at the tie plate seat for the placement of new tie plates. Afterward, debris and wood shavings are swept away from the tie plate seat area. The unit is equipped with two sweeper brooms or cribbers, one on either side of the adzer head.

TECHNICAL DETAILS

Frame: The main frame is of all-welded construction using heavy six inch tubular steel. Cross members are of channel and tubular steel with reinforcements.

Weight: 28,000 lbs. (12704 kg)

Engine: John Deere 6068 225hp @2400rpm, Tier IV Final

Propel System: 3 1/2 inch diameter solid steel alloy axles with direct chain drive from hydraulic motor to one axle. Propel during work mode is provided by dual crawler tracks on the adzer side. Maximum adzer/work speed is 80 feet-per-minute (25 m/min.). Maximum travel speed is 26 mph (42 km/h).

Wheels and Brakes: Four 16 inch (406 mm) diameter cast steel wheels with 3.5 inch (89 mm) diameter solid alloy steel axles. Spring applied, hydraulic released fail safe brakes on each wheel. Heavy duty axle bearings.

Adzer Head: Special design balanced solid steel adzer disk available in 16 inch. 18 inch, 19 inch, or 21 inch diameter- 4 bit configurations, 18 inch-6 bit, and 21 inch-8 bit configurations powered by a hydraulic motor. The machine is capable of adzing in either direction of travel.

Cribbers: The machine is equipped with two sweeper brooms or cribbers, one on either side of the adzer head. The brooms (cribbers) consist of 2-inch diameter solid rubber elements plus elements with steel “knocker” tubing swaged on the end mounted on a welded balanced steel reel powered by a hydraulic motor.

Electrical System: 24 volt dc negative ground. System maintained by engine driven alternator. Color coded and numbered wiring.

Hydraulic System: A closed loop type pump provides power to the adzing head and the rail travel wheels. A load sensing pump provides power for crawler functions, cribber motors, and all hydraulic cylinder functions.

Capacities:

Fuel: 100 gal (379 liters)

Hydraulic: 100 gal (379 liters).

Options: Dual cribbers on each end of the machine. Other options available upon request.

KERSHAW® MOW OVERVIEW

PARTS HOTLINE: 1-888-660-5252

SERVICE HOTLINE: 1-833-537-7782

SALES CONTACTS

RAIL EQUIPMENT SALES

VEGETATION EQUIPMENT SALES

INTERNATIONAL SALES

OEM PARTS, SERVICE & WARRANTY

KERSHAW DIRECTOR

Randy Chubaty

National Sales Manager - Rail

Fairmont, MN

507-384-2577

Jennifer Kincaid

Sales Executive - Rail

Bradenton, FL

414-369-9290