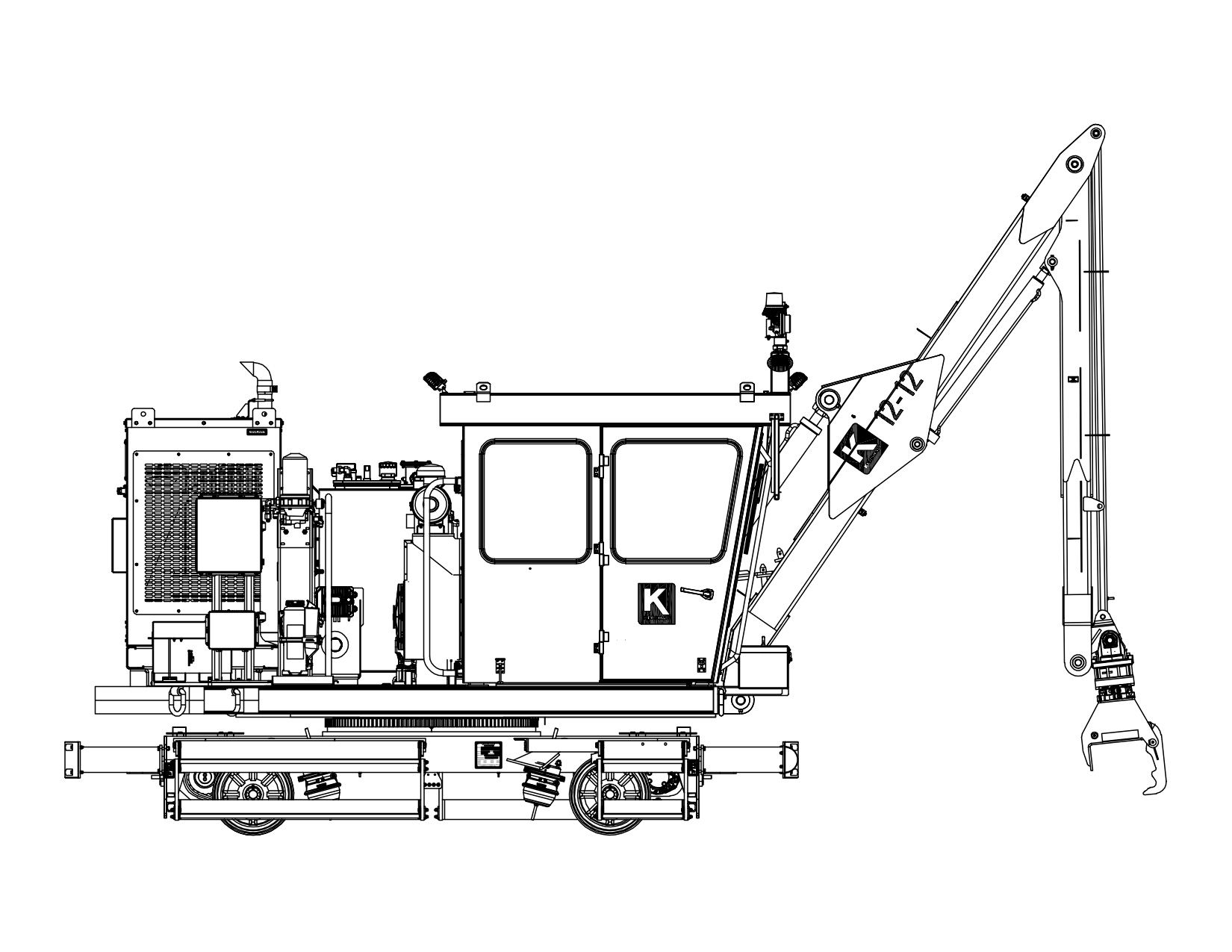

KERSHAW® 12-12 TIE/BRIDGE CRANE

Progress Rail’s Maintenance-of-Way (MOW) division was born out of the movement toward mechanization in the railroad industry and introduced the first Kershaw® Ballast Regulator in 1945. Today, Progress Rail supplies Kershaw® MOW equipment, providing machines to all Class I railroads, transit and short lines and contractors around the world.

The Kershaw® 12-12 Tie Crane has a maximum lifting capacity of 1200 lbs. (544 kg) at 25 ft. (7315 mm) from the center of the track. The upper deck and tie grapple are capable of 360° continuous rotation. Recent enhancements include Tier IV engines, redesigned upper and lower decks, enhancements to better accommodate hydraulic hosing and wiring and hydrostatic propel. Hydraulic brakes are offered as an option, eliminating the pneumatic system if desired.

Optional clamps turn this tie crane into a bridge crane.

TECHNICAL DETAILS

Frame: Welded construction, lower frame is structural steel and 1” (25.4 mm) thick steel plate for the slewing ring support. Upper deck is structural steel and formed deck plates. Frame covered by Five (5) Year Warranty. Oversize 46 7/8 inch diameter slewing ring rated for 80,000 ft-lb. Remote grease fittings for slewing ring and axle bearings. 8-channel 6,000 psi hydraulic swivel is accessible from upper deck.

Engine: Caterpillar C4.4, 131 hp @ 2200 rpm, Tier IV final

Transmission and Axles: 3” (76 mm) diameter solid axles with chain drive from separate hydraulic motors driving both axles. Travel speed: 20 mph (32 km/hr). Two (2) propel drive motors for quicker response in work mode. #100 drive chain with hardened tooth sprockets.

Hydraulic System: Hydrostatic propel pressure compensated piston type pump direct coupled to engine. Deck rotation by hydraulic motor through gearbox. Hydraulic oil is filtered through a 100 mesh (145 micron) suction screen and 10 micron return line filter. Manifold-type stack valves for improved serviceability. Remote oil cooler accessible from ground level with dual electric cooling fans. Electric emergency pump.

Electrical System: 24 volt DC negative ground, 100 amp alternator, color coded and numbered wiring

Air System: Air compressor, engine oil-lubricated, air-cooled; pressure - 100-120 psi (689-927 kPa), 15-gallon air tank

Cab: Large enclosed cab with 99.5 cubic foot capacity. Ergonomically designed seat. Large front windshield with an unobstructed view of boom operation through full range of motion. Hydraulic pilot-pressure bottom-ported joystick controls on operator seat with heat shields. Self-contained hydraulically driven air conditioner/heater/pressurizer unit mounted on rear wall of cab (roof mount optional). Remote controlled boom travel lock. Rubber suspension ladder steps. No service items located on cab roof on standard machine.

Wheels and Brakes: 16” (406 mm) cast steel wheels. External, individual composite brake shoes applied directly on the vertical centerline of wheel tread. Service brakes are air applied, spring released. Emergency/parking brakes are spring applied, air released.

Capacities: Fuel: 75 gal. (284 liters), Hydraulic: 70 gal. (265 liters)

Weight: 23,000 lbs.

Boom: Ultra-wide 32 inch (813 mm) spread base root boom mount. GV-12 grapple rotator. Single tie grapple.

Optional Equipment: Basket grapple; two tie grapple; timber grapple; concrete tie grapple; rail clamps; bridge crane package; timber crane package; boom winch; two-speed propel; boom-mounted flail mower.

KERSHAW® MOW OVERVIEW

PARTS HOTLINE: 1-888-660-5252

SERVICE HOTLINE: 1-833-537-7782

SALES CONTACTS

RAIL EQUIPMENT SALES

VEGETATION EQUIPMENT SALES

INTERNATIONAL SALES

OEM PARTS, SERVICE & WARRANTY

KERSHAW DIRECTOR

Randy Chubaty

National Sales Manager - Rail

Fairmont, MN

507-384-2577

Jennifer Kincaid

Sales Executive - Rail

Bradenton, FL

414-369-9290