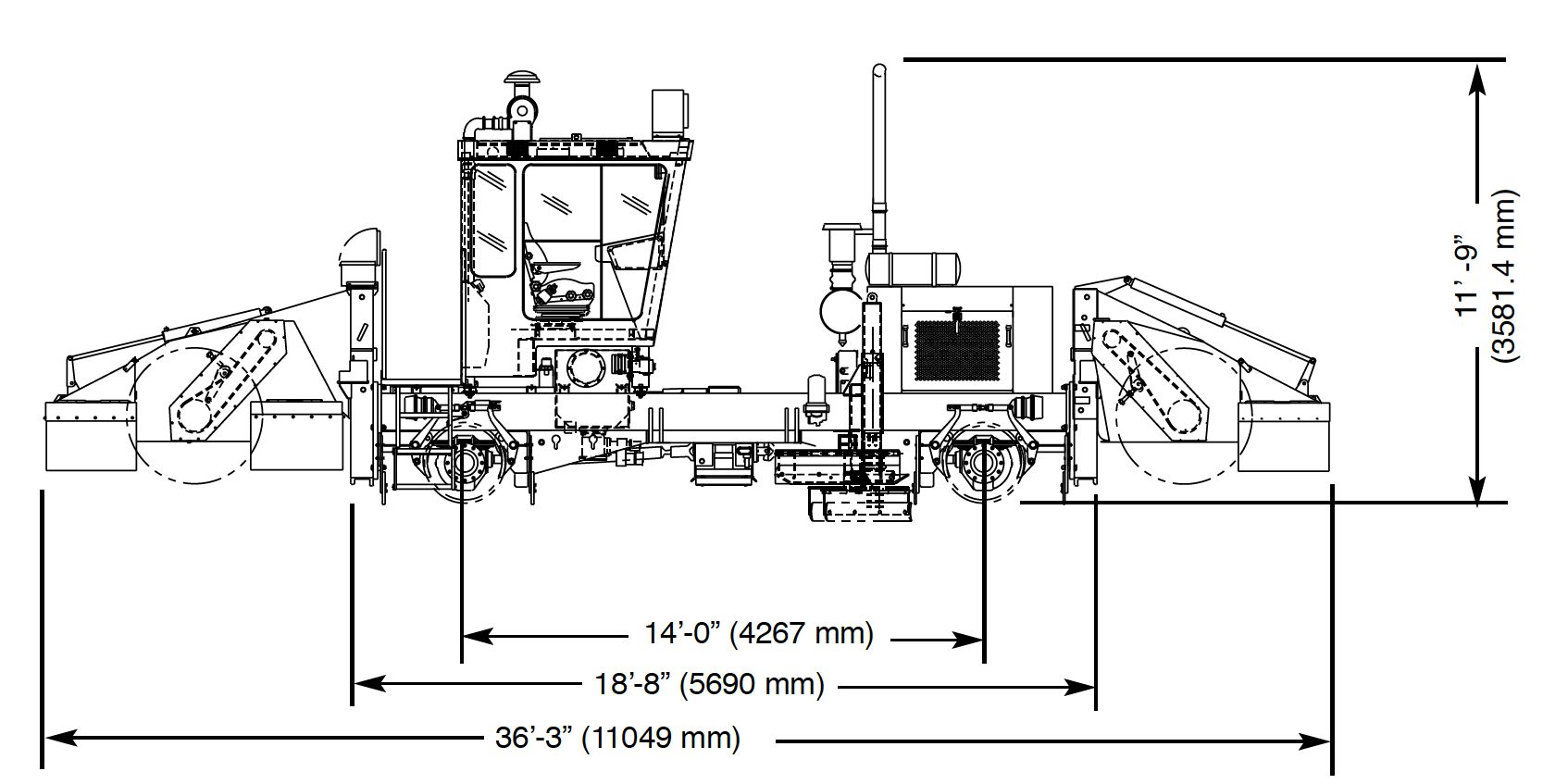

KERSHAW® 35-14 DOUBLE BROOM

Progress Rail’s Maintenance-of-Way (MOW) division was born out of the movement toward mechanization in the railroad industry and introduced the first Kershaw® Ballast Regulator in 1945. Today, Progress Rail supplies Kershaw® MOW equipment, providing machines to all Class I railroads, transit and short lines and contractors around the world.

The Kershaw® 35-14 has two broom attachments. The rear-mounted broom is reversible.

TECHNICAL DETAILS

Frame: Welded construction using tubular steel and structural steel cross members. Equipped with turntable.

Weight: 43,200 lbs.

Engine: Caterpillar® C7.1 250 @ 2200 rpm Tier IV Final

Propel System: Hydrostatic drive, variable displacement pump, variable displacement motor standard with two-speed shift on the go. Travel speed 35 mph.

Transmission and Axles: Propel motor powers two-speed transmission. Dual propeller shafts, two (2) spring-mounted industrial type axles equipped with no spin differential. Gear ratio is 6.14:1. Axle bearings do not require external lubrication. Single control handle controls speed and direction in each range.

Wheels and Brakes: 28" cast steel wheels bolted to each axle, clasp brakes (two brake shoes per wheel). Service brakes; air applied/spring released. Parking brakes; spring applied/air released.

Electrical System: 24 volt dc negative ground, two 205 amp/hour batteries, color coded and numbered wiring.

Air System: Air compressor, engine oil lubricated cam shaft driven, water-cooled, 20 ft. (566 liters) free air volume @ 2200 rpm. System pressure is 100 psi (6.8 atm), 613 in. 3 (9.8 liters) air tank. Service brakes are controlled by a manually-operated dump valve. System is also equipped with a dual tone air horn, safety relief vavle.

Hydraulic System: Engine-powered triple pump drive with hydrostatic propel pump and pumps for controls and brooms. Control circuit includes electrically actuated control valves and remote-mounted oil cooler. 100 mesh suction screens and 10 micron return filters. Fluid level indicators equipped with vandalism protection. Electric emergency pump to operate selected circuits. Filler cap on tank equipped with means for attaching padlock.

Cab: Fully enclosed, insulated safety glass windshield & rear windows, dome light, front windshiel wiper and pivoting adjustable seat, two variable speed 6" fans. Equipped with sealed beam lights. Access to cab from either side of machine. Equipped with self-contained hydraulically driven air conditioner/heater/pressurizer. Walkway equipped with safety chains. All attachment locks are operable from cab.

Capacities: Fuel 122.5 gallon (464 liters), hydraulic: 98 gallons (371 liters), engine crankcase: 12 qt. (11 liters), cooling system: 24 qt. (22.7 liters), pump drive: 4 1/2 qt. (4.2 liters) transmission: 2 qt. (1.9 liters) *Add 2 qts. (1.9 liters) for filter.

KERSHAW® MOW OVERVIEW

PARTS HOTLINE: 1-888-660-5252

SERVICE HOTLINE: 1-833-537-7782

SALES CONTACTS

RAIL EQUIPMENT SALES

VEGETATION EQUIPMENT SALES

INTERNATIONAL SALES

OEM PARTS, SERVICE & WARRANTY

KERSHAW DIRECTOR

Randy Chubaty

National Sales Manager - Rail

Fairmont, MN

507-384-2577

Jennifer Kincaid

Sales Executive - Rail

Bradenton, FL

414-369-9290